Revolutionizing Industrial Safety and Maintenance

Understanding Thermal Inspection

In modern industrial operations, preventive maintenance and safety monitoring are essential to ensure efficiency and reduce costly downtime. One of the most effective tools in achieving this is thermal inspection. This method involves using specialized equipment to measure heat patterns, detect anomalies, and identify potential issues before they escalate into serious problems.

A thermal inspection camera plays a crucial role in this process. Unlike traditional tools that rely on physical examination or visible-light cameras, a thermal inspection camera captures infrared radiation emitted by objects, allowing professionals to see temperature variations that are invisible to the naked eye. This technology has become indispensable across multiple industries for its ability to enhance safety, optimize operations, and support predictive maintenance strategies.

How Thermal Inspection Cameras Work

Infrared Technology

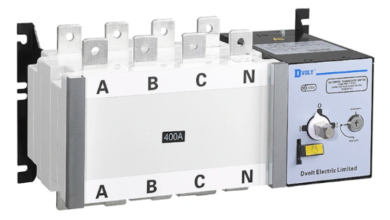

Thermal inspection cameras rely on infrared technology to detect heat emitted by surfaces. The camera converts infrared radiation into a visible image called a thermogram, where different colors represent different temperatures. This visual representation makes it easier to pinpoint overheating components, insulation gaps, or other irregularities in systems ranging from electrical panels to mechanical machinery.

For example, in an electrical switchboard, a loose connection can generate excess heat. While invisible to the human eye, a thermal inspection camera can immediately highlight this hot spot, allowing technicians to intervene before it causes damage or fire.

Key Features

Modern thermal inspection cameras come equipped with features that make inspections faster and more accurate:

- High-resolution imaging: Provides clear thermograms for precise analysis.

- Wide temperature ranges: Detects both low and high temperatures suitable for diverse applications.

- Portability: Lightweight and handheld models allow inspections in tight or hard-to-reach spaces.

- Data storage and analysis: Stores images and readings for documentation, reporting, and trend analysis.

Applications Across Industries

Electrical and Power Systems

Electrical infrastructure is highly sensitive to heat-related failures. Thermal inspection cameras are widely used to monitor power distribution panels, transformers, and circuit breakers. By identifying overheating circuits or faulty connections, technicians can prevent equipment failures, reduce fire risks, and maintain operational continuity.

Manufacturing and Mechanical Equipment

In manufacturing environments, machinery is exposed to continuous stress and wear. Thermal inspection cameras help monitor bearings, motors, pumps, and conveyor systems for abnormal heat patterns. Early detection allows maintenance teams to schedule repairs proactively, reducing unexpected downtime and avoiding costly production losses.

Building and Construction

In construction and building management, thermal inspection cameras are used to identify insulation inefficiencies, roof leaks, HVAC problems, and moisture intrusion. These inspections contribute to energy efficiency, lower utility bills, and improved occupant comfort while preventing long-term structural damage.

Oil, Gas, and Chemical Industries

Facilities in high-risk industries require precise monitoring to ensure safety. Thermal inspection cameras help detect leaks, corrosion, or equipment overheating in pipelines, storage tanks, and chemical reactors. This proactive approach is crucial for protecting personnel, equipment, and the environment.

Healthcare and Food Safety

Thermal inspection cameras are also valuable in healthcare and food industries. In medical facilities, they ensure that sterilization thermal inspection camera equipment functions correctly and that storage areas maintain proper temperatures for medications and vaccines. In the food industry, thermal inspections monitor refrigeration units, processing lines, and cooking equipment to maintain safety and quality standards.

Advantages of Thermal Inspection Cameras

Enhanced Safety

Using a thermal inspection camera allows technicians to identify hazards without direct physical contact. This is especially important in high-risk environments such as electrical substations or industrial machinery areas. Remote detection minimizes exposure to dangerous conditions while ensuring accurate assessments.

Cost Reduction

Preventing equipment failure through thermal inspections reduces repair costs and operational downtime. By identifying problems early, businesses can avoid costly replacements and maintain uninterrupted productivity.

Efficiency and Speed

Thermal inspection cameras provide instant visual feedback. This allows maintenance teams to quickly identify issues, prioritize repairs, and make informed decisions. Compared to traditional inspection methods, thermal inspections are faster and more comprehensive.

Non-Invasive Inspections

Unlike some diagnostic methods, thermal inspections are non-destructive. Equipment does not need to be dismantled, and operations can continue without interruption. This is particularly valuable in manufacturing plants, hospitals, or any environment where downtime is expensive or disruptive.

Regulatory Compliance

Many industries must adhere to safety and maintenance standards. Thermal inspection cameras provide documented evidence of proactive monitoring, which can be used for audits, regulatory compliance, and safety reporting.

See also: How Automation Technology Changes Employment

Best Practices for Effective Thermal Inspections

Regular Monitoring

Routine thermal inspections are essential for maintaining consistent monitoring of equipment and infrastructure. Establishing a schedule ensures early detection of issues and reduces the risk of unexpected failures.

Proper Training

Technicians must be trained to interpret thermograms accurately. Understanding normal operating temperatures and recognizing abnormal heat patterns are critical for effective predictive maintenance.

Integration with Predictive Maintenance

Thermal inspection cameras can complement predictive maintenance programs. Historical data and trend analysis allow maintenance teams to anticipate potential failures, optimize repair schedules, and reduce unplanned downtime.

Documentation and Reporting

Maintaining detailed records of thermal inspections is essential. This documentation supports maintenance planning, regulatory compliance, and internal communication, ensuring transparency and accountability.

Emerging Trends in Thermal Inspection

AI and Machine Learning

Artificial intelligence is increasingly integrated with thermal inspection cameras. AI can automatically detect anomalies, classify issues, and generate reports, reducing human error and increasing inspection efficiency.

Remote Monitoring

With IoT technology, thermal inspection cameras can transmit data in real time to centralized monitoring systems. This allows remote supervision of multiple sites or hazardous environments, enhancing response times and operational control.

Miniaturization and Portability

Smaller, lighter thermal inspection cameras are making inspections more convenient. Compact designs allow technicians to access confined spaces and perform rapid assessments without cumbersome equipment.

Expanded Applications

As industries recognize the value of thermal inspection, applications are expanding. Renewable energy, smart buildings, transportation, and infrastructure management are increasingly using thermal inspection cameras to optimize safety, efficiency, and sustainability.

Conclusion

Thermal inspection is a transformative technology in modern industrial and commercial operations. A thermal inspection camera enables businesses to identify hidden issues, monitor equipment performance, and implement proactive maintenance strategies.

From electrical systems and manufacturing machinery to building management, healthcare, and high-risk industries, the applications of thermal inspection are diverse and impactful. By integrating this technology into routine monitoring and predictive maintenance programs, organizations can achieve enhanced safety, reduced costs, and improved operational efficiency.

With advancements in AI, IoT, and portable designs, thermal inspection cameras will continue to revolutionize maintenance strategies, ensuring industries remain safe, efficient, and prepared for the challenges of the future.